HCl Distillation Plant

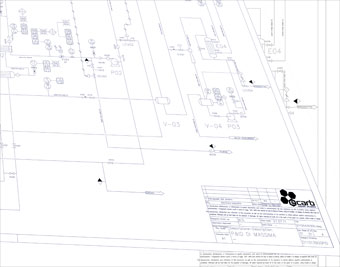

Graphec® OneButton systems offer taylor-made solutions for Hydrochloric Acid distillation. Premium systems which ensure the minimum investment cost thanks to internal production of critical items.

Pressure swing iper-azeotropic distillation: two distillation stages working at different pressure (one under vacuum conditions, the other with high pressure) allow to distillate Hydrocloridric Acid over azeotropic concentration (~20% at atmospheric pressure), exploiting the change of azeotropic concentration with pressure.

Extractive distillation of HCl with Sulfuric Acid. In order to exceed azeotropic concentration, it is possible to use the great hygroscopic properties of Sulfuric Acid, which dehydrates diluted Hydrocloridric Acid, inside an extracting column. A second column recovers spent aulfuric acid, to recirculate it to extractino column. This recycle reduces drastically acid consumption. Each stage of the process needs an accurate material selection, in order to guarantee longer operating life of equipment.

Azeotropic distillation (purification): azeotropic solutions of HCl are evaporated and condensate in single or double stage evaporator, to remove traces of metallic ions (Fe,Zn,Pb,….) or other heavy compounds.